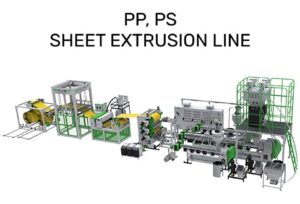

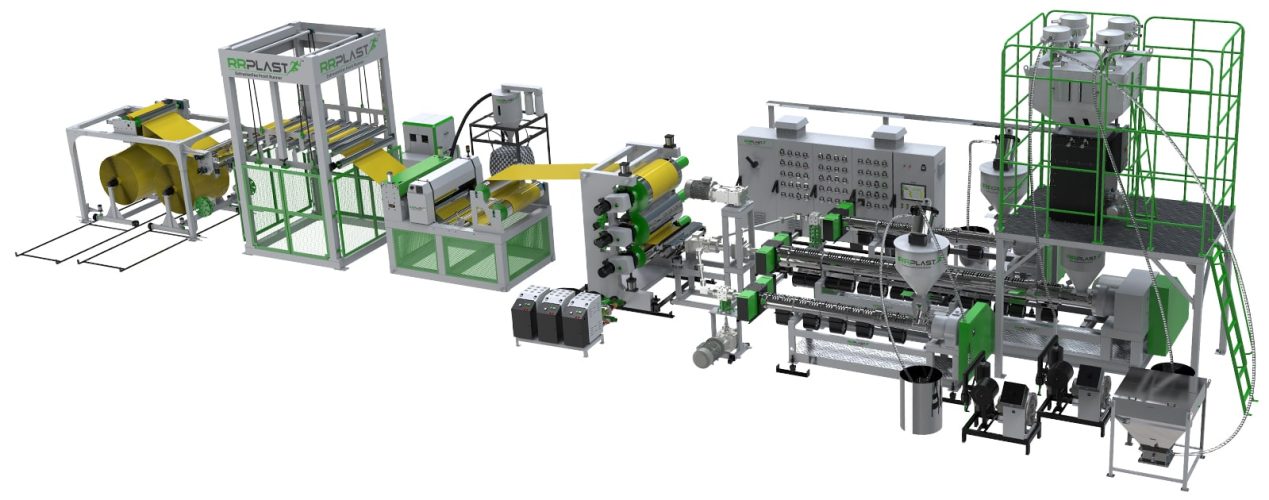

PP, PS SHEET EXTRUSION LINE

The manufacturing of sheet extrusion lines for PP and PS remains one of the main activities of RR Plast. We can provide a wide range of sheet lines, for example:

- Smaller-sized extrusion equipment, with the possibility of “in-line” thermoforming activities.

- Higher output extrusion sheet lines for off-line production.

Unique features:-

- High Capacity

- Auto material loading system

- Stable Running

- Thickness scanner

- Sheet accumulator

- Auto roll gap adjustment

With the wide selection of roller widths and diameters, nearly all the thermoforming requirements can be fulfilled. Different types of sheet winding systems are available in order to meet each customer’s specific requirement. Our delivery program includes different solutions from a small cantilever double winder to a jumbo two or four-station winding system with moveable A-Frames plus automatic sheet cutting.

Main Technical Parameters

| Model | Unit | 100/30 | 120/30 | 150/33 | 150/33-100/30 | 200/33-100/30 |

| Sheet Thickness | mm | 0.3-2 | 0.3-2 | 0.3-2 | 0.4-2 | 0.4-2 |

| Sheet Width | mm | 800-1000 | 800-1000 | 1200 | 1600 | 1800 |

| Motor | Kw | 90 | 160 | 200 | 200/901 | 400/90 |

| Output | kg/hr | 300-400 | 600-800 | 800-1000 | 1200 – 1400 | 1800-2000 |

| Roll Dia | cm | Ø 40 | 40 | 40 | Ø 40 | 50 | 50 | Ø 40 | 60 | 60 | Ø 50 | 70 | 70 | Ø 50 | 70 | 70 |

| Model | Unit | 100/30 | 120/30 | 150/33 | 150/33-100/30 | 200/33-100/30 |

| Sheet Thickness | mm | 0.3-2 | 0.3-2 | 0.3-2 | 0.4-2 | 0.4-2 |

| Sheet Width | mm | 800-1000 | 800-1000 | 1200 | 1600 | 1800 |

| Motor | Kw | 90 | 160 | 200 | 200/901 | 400/90 |

| Output | kg/hr | 300-400 | 600-800 | 800-1000 | 1200 – 1400 | 1800-2000 |

| Roll Dia | cm | Ø 40 | 40 | 40 | Ø 40 | 50 | 50 | Ø 40 | 60 | 60 | Ø 50 | 70 | 70 | Ø 50 | 70 | 70 |

Note: The specification is subject to change without prior notice.

Applications

PP SHEET ROLL

MEAL TRAY