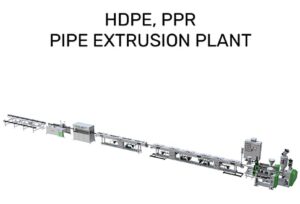

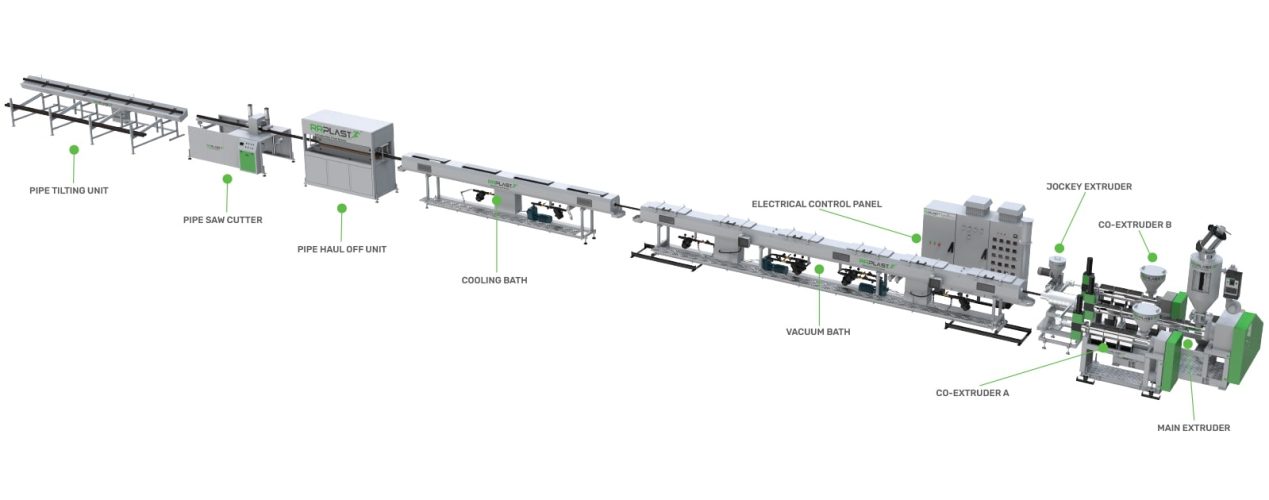

HDPE, PPR PIPE EXTRUSION PLANT

Features

- Next-generation barrier screws with longer L/D (33/36/40 D) are standard for

- Polyolefins

PE 63/80/100 – grade processing possible - Accurate control of the melt conditions, homogeneous temperatures and pressures without variation, surging & low thermal stresses

- Consistent throughput for all screw speeds

- The drive motor and the gearbox can be directly coupled or belt driven as per torque requirement to achieve the optimum efficiency to reduce the power consumption per unit output

- The screws and barrels are normally supplied in nitrided steel.

- Bimetallic high wear-resistant barrels can be supplied for high-speed extruder

- Special design 3-layer pipe plant (A-B-A or A-B-C)

- Model range 20 mm to 110 mm, 63 mm-200 mm, 75 mm, 315 mm

Output 200/300/400/500/750 kg/h

| Technical Specifications | |||

| Pipe Size (MM) | Layer | Output | Material |

| 20 to 315mm | Mono / Multilayer (A-B/A-B-A/A-B-C type) | 250 – 750 kg/h | PE63/PE80/PE100 |

| Technical Specifications | |||

| Pipe Size (MM) | Layer | Output | Material |

| 20 to 315mm | Mono / Multilayer (A-B/A-B-A/A-B-A type) | 140 – 1200 kg/h | PE63/PE80/PE100 |

Note: The specification is subject to change without prior notice.

Applications

SPRINKLER & WATER SUPPLY PIPES

PE GAS PIPE